- HOME

- standard lineup

- three-dimensional nozzle

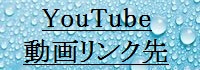

Three-dimensional Nozzle ( 3-D nozzle )

Hi-jet series

High pressure washer nozzle, high-jet series is a 3-D nozzle for complete cleaning automatically inside for mixing tank, polymer resin tank, the polymerization vessel, reaction kettle, storage tanks, cans, etc.

Feature

- No oil leakage so very safe for the rotational movement because of oil-free movement.

- Successful Lightweight, compact module. Can be inserted from the narrow caliber, workability has increased drastically.

- Use a polymer resin and stainless steel main material, range for use of a detergent has been expanded.

- For working in narrow spaces and heights, can be design, wide lifting device.

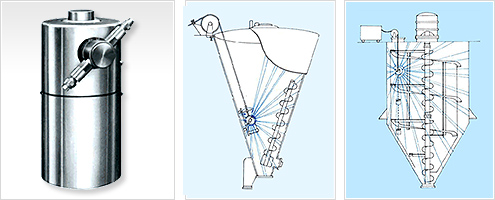

TM-13 Main specification

| Model | TM-13L | TM-13H |

|---|---|---|

| Pressure | 2.0~10MPa | 11~20MPa |

| Nozzle Orifice | 2.0~2.7φmm | 1.4~2.4φmm |

| Flow Rate | 25~100L/min | 32~115L/min |

| Rotation | 4~6rpm | 5~8rpm |

| Rotary Ratio | about 1:1 | |

| Cycle Time | 5~7.5min | 4~6min |

| Drive Type | Turbine | |

| Main Materials | SUS304 | |

| Surface Treatment | Out Side Buffing | |

| Heat Resistanse | 60℃ | |

| Joint | Rc1/2 | |

| Weight | 4kg | |

THA-300 Main specification

| Model | THA-300 |

|---|---|

| Pressure | 0.1~30MPa |

| Flow Rate | 10~86L/min |

| Rotation | 5~10rpm |

| Rotary Ratio | about 1:1 |

| Cycle Time | 4~7min |

| Drive Type | Air-Motor |

| Main Materials | SUS304 PTFE |

| Joint | Rc1/2 |

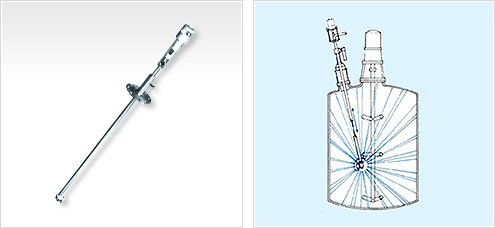

Clean Jet

Feature

- No oil leakage so very safe for the rotational movement because of oil-free movement.

- Successful Lightweight, compact module. Can be inserted from the narrow caliber, workability has increased drastically.

- Use a polymer resin and stainless steel main material, range for use of a detergent has been expanded.

- For working in narrow spaces and heights, can be design, wide lifting device.

Direction

- Food manufacturing (Brewing tank, distillation kettle, storage tank, food tanks, etc).

- Chemical Manufacturing (Reaction tank, storage tank, etc.)

- Spinning industry, the oil industry, marine industry, steel industry, nuclear industry, other.

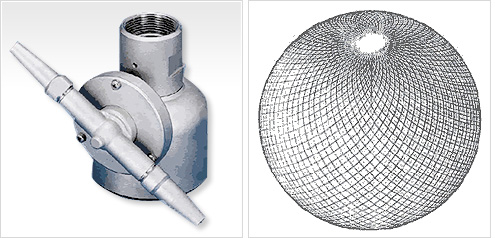

TC-10 Main Specification

| Model | TC-10 |

|---|---|

| Pressure | 0.3~0.8MPa |

| Nozzle Orifice | 7~10φmm(2) |

| Flow Rate | 140~380L/min |

| Effective Distance | 2.5~9m |

| Spray Coverage | 360° |

| Rotation | 3~6rpm |

| Rotary Ratio | about 1:1 |

| Cycle Time | 13~17min |

| Drive Type | Turbine |

| Main Materials | SC13 SUS304 PTFE |

| Surface Treatment | Out Side Buffing(#300) |

| Working Temperature (Max) | while the operating 80℃ shut down period 120℃ |

| Joint | R2 |

| Weight | about 11kg |

| Demensions | L110×W165×H245mm |

TC-X Main specification

| Model | TC-X |

|---|---|

| Pressure | 0.3~0.8MPa |

| Nozzle Orifice | 7~9φmm(normal 8φmm) |

| Flow Rate | 100~245L/min |

| Effective Distance | 2.5~8m |

| Rotation | 2~3rpm |

| Cycle Time | 約14~35min |

| Drive Type | Turbine |

| Main Materiasl | SUS304 Carbon/PTFE |

| Surface Treatment | Option:Buffing(#300) |

| Working Temperature(Max) | 60℃(Heat Resistance 80℃) |

| Joint | Rc1 1/2(40A) |

| Weight | 4kg |

TC-X Y Main Specification

| Model | TC-X Y |

|---|---|

| Pressure | 0.3~0.8MPa |

| Nozzle Orifice | 7φmm |

| Flow Rate | 110~175L/min |

| Effective Distance | 3m |

| Rotation | (2-3)~5rpm |

| Cycle Time | aout 14~35min |

| Drive Type | Turbine |

| Main Materials | SUS304 carbon/PTFE |

| Surface Treatmant | Option:Buffing(#300) |

| Working Temperature(Max) | 60℃(Heat Resistance 80℃) |

| Joint | Rc1 1/2(40A) |

| Weight | 4kg |